The process starts in the home where waste is sorted into dry recyclables (paper, card and plastics) and general waste, with some local authorities also offering food waste and a glass bottle collection.

Beyond this point, the waste goes to Material Recovery Facilities (MRF’s) where semi and fully automated processes refine the waste into re-usable commodities like plastics, paper, glass, and metals. Organic waste from food etc. is generally anaerobically digested producing rich compost and methane which can be recovered. The Methane and separately other waste materials can be combusted at specialist sites to create waste to energy electricity and heat that either run the MRF plant or subsidise the power grid.

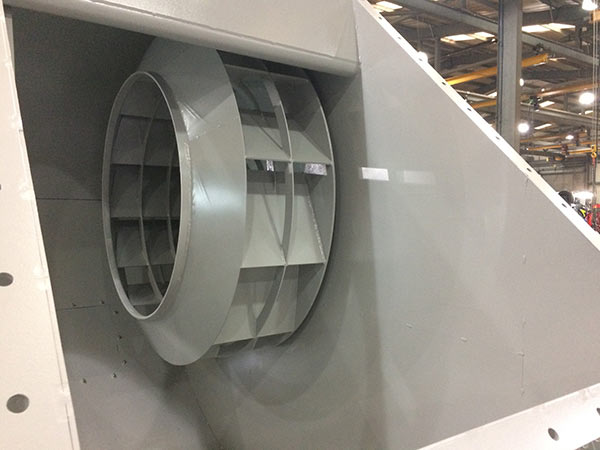

This fan has recently been shipped to a new state of the art MRF facility in Cheshire.

Features:

- 1.6M Impeller

- 160KW motor

- High-efficiency Beaufort Impeller design

- Halifax M-Type bearing Unit

- C5 Chemical/Marine paint system